G series 80~100mm

| Availability: | |

|---|---|

| Quantity: | |

Advantages:

The equipment features a prestressed steel-wire wound structure for its high-pressure vessel, frame, and booster, achieving a working pressure of 200MPa. This design is currently recognized as the mechanical configuration with the highest safety factor and longest service life. The dry bag has an inner diameter of 80-100mm, making it suitable for compacting small, rod-shaped, or tubular components.

The working fluid inside the high-pressure vessel remains in a sealed state throughout the entire working cycle, completely eliminating the possibility of powder mixing into the working medium inside the high-pressure chamber and improving the overall reliability of the equipment. As a result, the working medium will not be taken out of the equipment, with zero loss, ensuring a clean working environment.

The equipment adopts the method of external loading, and the assembled mold is manually sent into the bracket to start automatic circulation. The structure is simple and the working efficiency is high.

The whole machine adopts servo hydraulic system, the working process is ultra-silent, so the labor environment is optimized.

Advantages:

The equipment features a prestressed steel-wire wound structure for its high-pressure vessel, frame, and booster, achieving a working pressure of 200MPa. This design is currently recognized as the mechanical configuration with the highest safety factor and longest service life. The dry bag has an inner diameter of 80-100mm, making it suitable for compacting small, rod-shaped, or tubular components.

The working fluid inside the high-pressure vessel remains in a sealed state throughout the entire working cycle, completely eliminating the possibility of powder mixing into the working medium inside the high-pressure chamber and improving the overall reliability of the equipment. As a result, the working medium will not be taken out of the equipment, with zero loss, ensuring a clean working environment.

The equipment adopts the method of external loading, and the assembled mold is manually sent into the bracket to start automatic circulation. The structure is simple and the working efficiency is high.

The whole machine adopts servo hydraulic system, the working process is ultra-silent, so the labor environment is optimized.

Control system: Adopt the Omron PLC control modules, with the servo system, to achieve the accurate control of the whole process of pressure rise / relief.

1. Using an Omron PLC control module, coupled with a servo system, precise control is achieved throughout the entire process of pressure increase and decrease.

2. Using the 10” full-color touch screen of OMRON, and the system responds quickly when the operator touches the button on the screen.

3. Friendly human-computer interface, easy to set parameters and check operation conditions. The pressing process curve can be directly viewed in the interface, or the corresponding pressing data can be outputted to the PC by USB flash disk for viewing and storage.

4. The membrane switch is attached to the surface of the control cabinet, and its graphical design with lights is easy to understand.

5. The hydraulic system adopts the servo motor and its matching oil pump, which can accurately control the pressure rise and fall process. The operation process is quiet and stable, and the energy consumption is much lower than that of the traditional oil pump motor group.

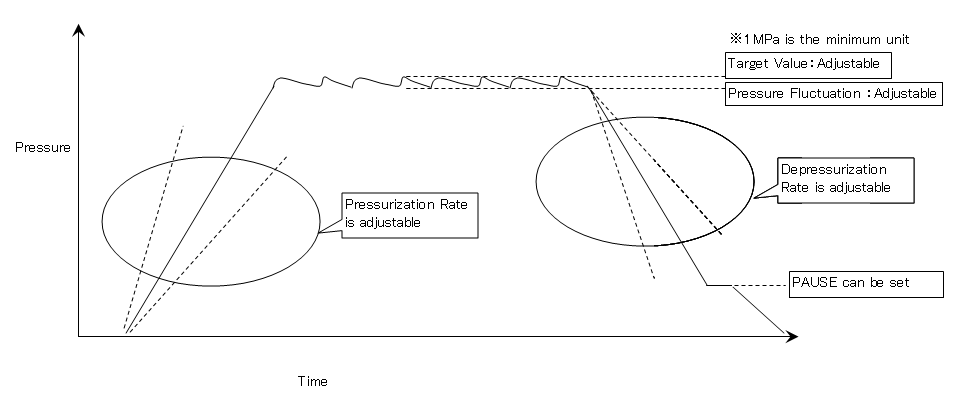

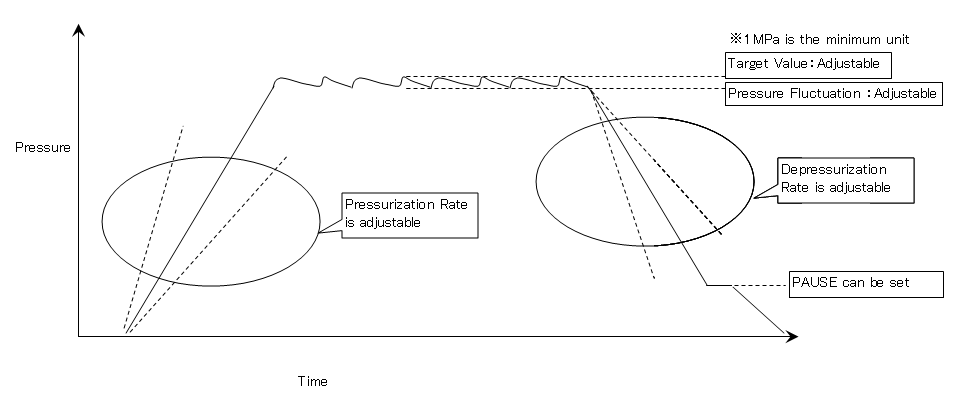

The process parameters can be set as follows:

Control system: Adopt the Omron PLC control modules, with the servo system, to achieve the accurate control of the whole process of pressure rise / relief.

1. Using an Omron PLC control module, coupled with a servo system, precise control is achieved throughout the entire process of pressure increase and decrease.

2. Using the 10” full-color touch screen of OMRON, and the system responds quickly when the operator touches the button on the screen.

3. Friendly human-computer interface, easy to set parameters and check operation conditions. The pressing process curve can be directly viewed in the interface, or the corresponding pressing data can be outputted to the PC by USB flash disk for viewing and storage.

4. The membrane switch is attached to the surface of the control cabinet, and its graphical design with lights is easy to understand.

5. The hydraulic system adopts the servo motor and its matching oil pump, which can accurately control the pressure rise and fall process. The operation process is quiet and stable, and the energy consumption is much lower than that of the traditional oil pump motor group.

The process parameters can be set as follows:

| Model | KJYge80 | KJYge100 |

| I.D. of dry-bag(mm) | 80 | 100 |

| Useful depth of High-pressure vessel(mm) | 400 | 400 |

| Maximum working pressure (MPa) | 30~200 | 30~200 |

| Dimensions (mm) | About 1700 × 1200 × 2300 | |

| Equipment weight (t) | 4 | |

| Single working cycle time (min) | 2~3 | |

| Installed power (Kw) | 16 | |

| Loading method | External loading | |

| Buck-boost rate | Can be set | |

| Working medium | Special oil for isostatic press | |

| HMI | Full color touch screen | |

| Record data export interface | USB interface | |

| Drive method | Hydraulic drive and auxiliary pneumatic drive | |

| Cooling method | Oil chiller forced cooling | |

| Model | KJYge80 | KJYge100 |

| I.D. of dry-bag(mm) | 80 | 100 |

| Useful depth of High-pressure vessel(mm) | 400 | 400 |

| Maximum working pressure (MPa) | 30~200 | 30~200 |

| Dimensions (mm) | About 1700 × 1200 × 2300 | |

| Equipment weight (t) | 4 | |

| Single working cycle time (min) | 2~3 | |

| Installed power (Kw) | 16 | |

| Loading method | External loading | |

| Buck-boost rate | Can be set | |

| Working medium | Special oil for isostatic press | |

| HMI | Full color touch screen | |

| Record data export interface | USB interface | |

| Drive method | Hydraulic drive and auxiliary pneumatic drive | |

| Cooling method | Oil chiller forced cooling | |

|  |  |

|  |  |

|  |  |  |

|  |  |  |