U300

| Availability: | |

|---|---|

| Quantity: | |

Advantages:

Intuitive touch interface with full-color graphics.

Setting and control of high-precision pressure curve. The whole pressure cycle data recordable and traceable, which makes it possible to compare the difference of deforming effects of materials under different isostatic pressing processes.

Accurate control of servo system, quiet and smooth operation, lower energy consumption than traditional oil pump generator system.

Convenient automatic lifting and charging, without any auxiliary equipment.

With the floor area of less than 4m2, it is easy for placement and saves more production space for users.

Advantages:

Intuitive touch interface with full-color graphics.

Setting and control of high-precision pressure curve. The whole pressure cycle data recordable and traceable, which makes it possible to compare the difference of deforming effects of materials under different isostatic pressing processes.

Accurate control of servo system, quiet and smooth operation, lower energy consumption than traditional oil pump generator system.

Convenient automatic lifting and charging, without any auxiliary equipment.

With the floor area of less than 4m2, it is easy for placement and saves more production space for users.

Control system: Adopt the Omron PLC control modules, with the servo system, to achieve the accurate control of the whole process of pressure rise / relief.

1. Adopt the 10in. full-color touch screen of OMRON, and the system will make an immediate response after your figures touch the button on the screen, which is more in line with the operation habits of perators.

2. Friendly human-computer interface, easy to set parameters and check operation conditions. The pressing process curve can be directly viewed in the interface, or the corresponding pressing data can be exported to the PC by USB flash disk for viewing and storage.

3. The membrane switch is attached to the surface of the control cabinet, and its graphical design with lights makes it easy to be understood.

4. The core oil pump generator system adopts excellent servo pump and supporting control motor to accurately control the whole process of pressure rise / relief, ensure the quiet and smooth operation under lower energy consumption than traditional oil pump generator system.

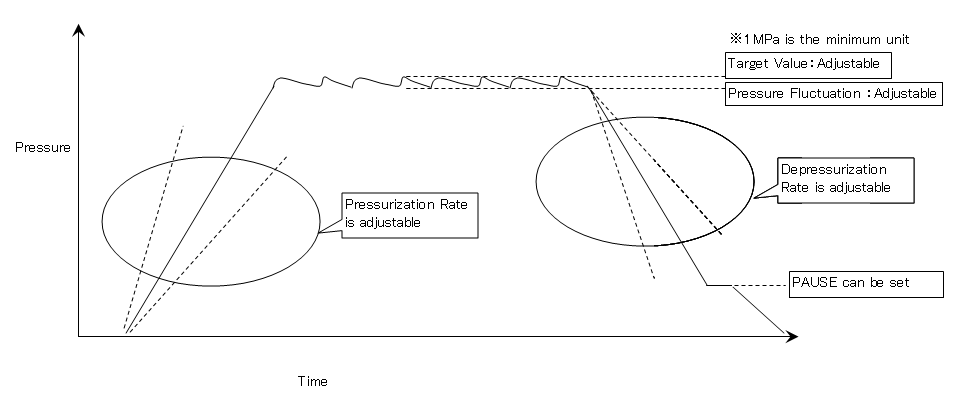

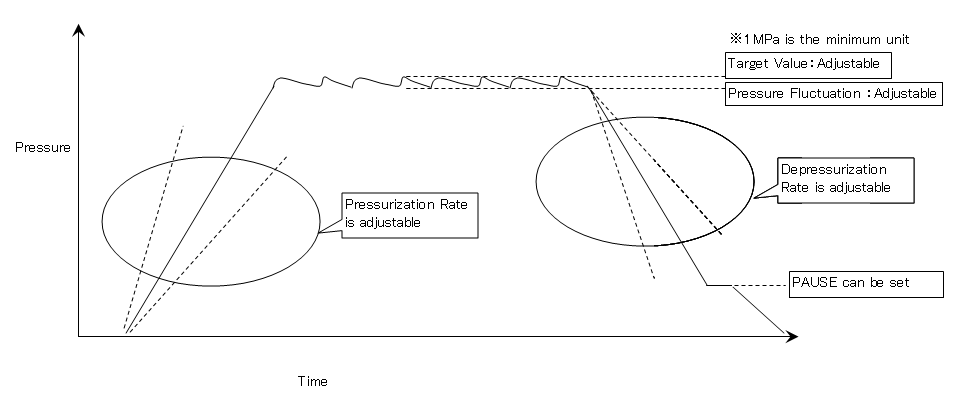

The process parameters can be set as follows:

Control system: Adopt the Omron PLC control modules, with the servo system, to achieve the accurate control of the whole process of pressure rise / relief.

1. Adopt the 10in. full-color touch screen of OMRON, and the system will make an immediate response after your figures touch the button on the screen, which is more in line with the operation habits of perators.

2. Friendly human-computer interface, easy to set parameters and check operation conditions. The pressing process curve can be directly viewed in the interface, or the corresponding pressing data can be exported to the PC by USB flash disk for viewing and storage.

3. The membrane switch is attached to the surface of the control cabinet, and its graphical design with lights makes it easy to be understood.

4. The core oil pump generator system adopts excellent servo pump and supporting control motor to accurately control the whole process of pressure rise / relief, ensure the quiet and smooth operation under lower energy consumption than traditional oil pump generator system.

The process parameters can be set as follows:

The entire equipment adopts a thickened sheet metal shell fully wrapped design, and all high-pressure components are installed inside the equipment. There are multiple security protection settings to ensure the safety production of the isostatic press

1. Manual pressure relief valve. In case of any emergency or failure, open the valve manually to enable the pressure relief protection, and the pressure can be increased again after closing it.

2. The hydraulic system has a preset pressure value, and when the preset pressure value is exceeded, the relief valve will automatically overflow.

3. Pressure sensor and electrical apparatus control system. When the pressure is higher than the preset pressure value, the electrical control system automatically stops the operation of the boosting system.

4. The control cabinet is equipped with an emergency stop button. After starting, the equipment can stop working in any working stage.

5. Interlocking of electrical control procedures. The equipment runs in strict accordance with the working procedure. If the previous procedure is not completed or there is a malfunction, the next procedure cannot be carried out, and the operation fault message will be sent out. After troubleshooting, the working can continue.

The entire equipment adopts a thickened sheet metal shell fully wrapped design, and all high-pressure components are installed inside the equipment. There are multiple security protection settings to ensure the safety production of the isostatic press

1. Manual pressure relief valve. In case of any emergency or failure, open the valve manually to enable the pressure relief protection, and the pressure can be increased again after closing it.

2. The hydraulic system has a preset pressure value, and when the preset pressure value is exceeded, the relief valve will automatically overflow.

3. Pressure sensor and electrical apparatus control system. When the pressure is higher than the preset pressure value, the electrical control system automatically stops the operation of the boosting system.

4. The control cabinet is equipped with an emergency stop button. After starting, the equipment can stop working in any working stage.

5. Interlocking of electrical control procedures. The equipment runs in strict accordance with the working procedure. If the previous procedure is not completed or there is a malfunction, the next procedure cannot be carried out, and the operation fault message will be sent out. After troubleshooting, the working can continue.

| Model | KJYu300 |

| Useful diameter of High-pressure vessel(mm) | 300 |

| Useful depth of High-pressure vessel(mm) | 400 |

| Maximum working pressure (MPa) | 200/250/300 |

| Heating function | The temp. can be raised to 80~120 ℃ according to customer requirements |

| Installed power (Kw) | 25 |

| Feeding method | Automatic picking |

| Buck-boost rate | Can be precisely set in sections |

| Working medium | Oil or Water-based antirust agent |

| HMI | Full color touch screen |

| Record data export interface | USB |

| Drive method | Hydraulic drive |

| Cooling method | Forced cooling by built-in Oil chiller |

| Dimensions (mm) | Not more than 2000×1600×2650 |

| Weight(t) | 11 |

| Model | KJYu300 |

| Useful diameter of High-pressure vessel(mm) | 300 |

| Useful depth of High-pressure vessel(mm) | 400 |

| Maximum working pressure (MPa) | 200/250/300 |

| Heating function | The temp. can be raised to 80~120 ℃ according to customer requirements |

| Installed power (Kw) | 25 |

| Feeding method | Automatic picking |

| Buck-boost rate | Can be precisely set in sections |

| Working medium | Oil or Water-based antirust agent |

| HMI | Full color touch screen |

| Record data export interface | USB |

| Drive method | Hydraulic drive |

| Cooling method | Forced cooling by built-in Oil chiller |

| Dimensions (mm) | Not more than 2000×1600×2650 |

| Weight(t) | 11 |

Design Patent Certificate

Design Patent Certificate

CE Certificate

Design Patent Certificate

Design Patent Certificate

CE Certificate